What’s the difference between technical and commercial ship management? Learn how each plays a vital role in ship operations and why understanding these ship management types is essential for modern maritime professionals.

Why Understanding Ship Management Types Matters in Modern Maritime Operations

Behind every successful voyage—whether it’s a container ship crossing the Pacific or a chemical tanker loading in the Persian Gulf—there are two silent engines working onshore: technical management and commercial management. Together, they form the foundation of modern ship operations.

In an era of complex regulations, decarbonization pressures, and rising costs, shipowners often delegate responsibilities to specialized managers. But these roles are not the same. Knowing the difference between technical and commercial ship management is crucial—especially for shipowners, charterers, seafarers, and maritime students aiming to enter this dynamic sector.

According to Clarksons Research (2024), over 70% of merchant vessels are under third-party management. Yet confusion often arises around who is responsible for what—maintenance vs. marketing, safety vs. strategy. This guide will break it all down for you.

What Is Ship Management? The Basics

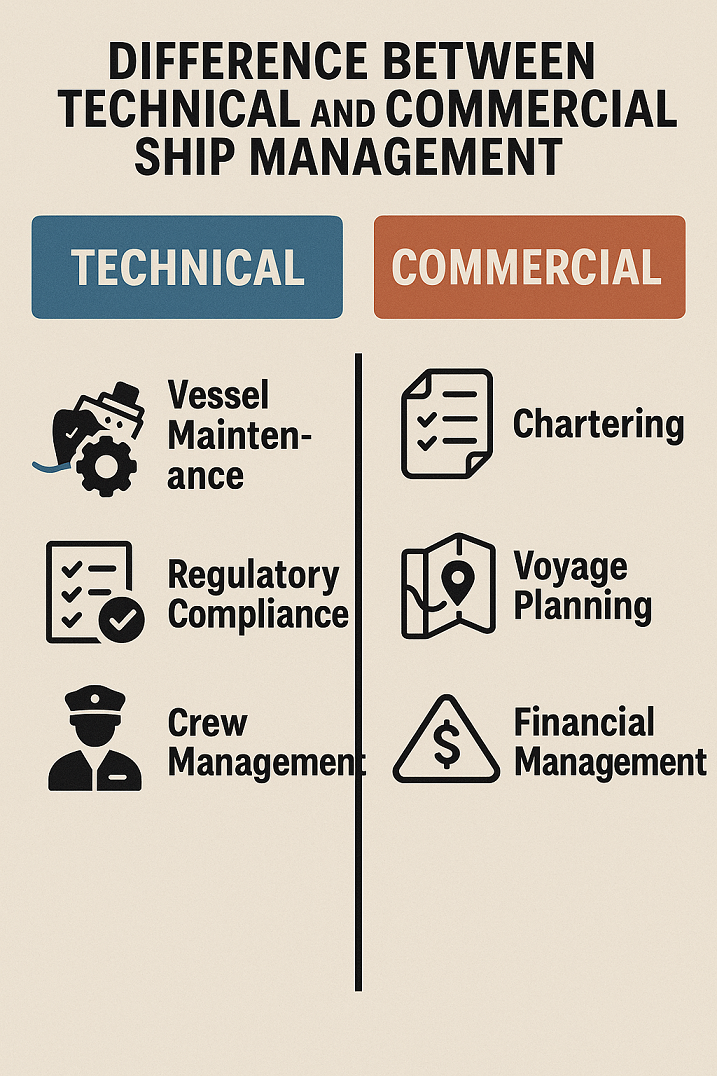

At its core, ship management refers to the wide range of services required to ensure a vessel is safely operated, fully compliant, commercially active, and profitable. These responsibilities are often divided into two major streams:

-

Technical ship management: Focuses on the physical vessel—its condition, crew, equipment, and compliance.

-

Commercial ship management: Focuses on making money from the ship—through chartering, cargo contracts, and voyage planning.

Let’s explore each in more detail.

Technical Ship Management Explained

Technical management involves all the engineering, maintenance, and crew-related functions needed to keep a ship seaworthy, safe, and compliant with international rules.

Core Responsibilities of Technical Management

-

Planned Maintenance: Regular servicing of main engines, generators, pumps, and hull inspections.

-

Dry-docking and Repairs: Scheduling, budgeting, and supervising yard work, often every 2.5–5 years.

-

Crew Management: Recruitment, certification, payroll, medical checks, and rotation planning.

-

Regulatory Compliance: Ensuring the vessel meets IMO standards (SOLAS, MARPOL, ISM), MLC 2006 for crew welfare, and class requirements (from societies like DNV, ABS, BV, ClassNK).

-

Procurement: Ordering spare parts, lubricants, and safety equipment.

-

Audits and Surveys: Regular internal and third-party inspections.

A vessel under good technical management is not only safer—it performs better, lasts longer, and is less likely to be detained by port state control.

Example: Anglo-Eastern’s Technical Management division monitors vessel performance via real-time dashboards and predictive maintenance, reducing emergency breakdowns by up to 30% (Thetius, 2023).

–

Commercial Ship Management Explained

Commercial management ensures that the ship is employed in a profitable and efficient way, maximizing returns for its owners or operators.

Core Responsibilities of Commercial Management

-

Chartering: Finding cargo and negotiating freight contracts (spot, time, voyage).

-

Freight Collection: Managing payments, claims, and demurrage.

-

Voyage Planning: Optimizing fuel use, port scheduling, and compliance with environmental limits (ECA zones, CII rating).

-

Market Analysis: Tracking trends in freight rates, bunker prices, and geopolitical risks.

-

Performance Monitoring: Evaluating voyage profitability using KPIs (e.g., TCE – Time Charter Equivalent).

A commercially well-managed ship doesn’t just sail—it earns.

Example: V.Ships’ commercial management arm uses real-time analytics to decide on voyage routes that reduce fuel costs by 8–12%, using dynamic weather routing and market forecasting (Lloyd’s Maritime Academy, 2024).

–

Technical vs Commercial Ship Management: Side-by-Side Comparison

| Feature | Technical Management | Commercial Management |

|---|---|---|

| Focus | Vessel condition, safety, compliance | Revenue generation, market performance |

| Main Services | Maintenance, crewing, repairs, audits | Chartering, voyage planning, freight management |

| Primary Tools | PMS software, class reports, crew apps | Market analytics, voyage simulators, bunker reports |

| Main Stakeholders | Engineers, superintendents, class societies | Charterers, brokers, commercial analysts |

| Regulatory Compliance | SOLAS, MARPOL, ISM, MLC 2006 | CII, EU ETS, SEEMP Part III |

| Performance Metrics | Downtime, detentions, crew turnover | Freight earnings, TCE, voyage efficiency |

How They Work Together: A Real-World Voyage Example

Imagine an Aframax tanker managed by a third-party ship manager.

-

Technical Team: Prepares the vessel in dry dock, certifies crew, checks hull integrity, and installs a scrubber to meet IMO 2020 sulfur regulations.

-

Commercial Team: Negotiates a six-month time charter with a major oil trader, tracks market rates, and plans voyages to reduce fuel consumption and maximize returns.

Without good technical management, the ship might break down mid-voyage. Without commercial expertise, it might sit idle at port—losing revenue every day.

–

Challenges and Solutions in Technical vs Commercial Management

Regulatory Overload

From the IMO’s GHG strategy to the EU Emissions Trading Scheme (ETS), managers must now handle a dense web of compliance. Solution? Smart software platforms like ABS MyDigitalFleet™ or DNV Veracity that integrate technical and commercial KPIs.

Skills Gap

Finding marine engineers or commercial analysts with real-time digital and compliance awareness is difficult. Some companies partner with institutions like the WMU (World Maritime University) and Massachusetts Maritime Academy to develop hybrid talent.

Cost Pressures

Owners often demand maximum efficiency with minimal OPEX. This forces both technical and commercial managers to prioritize data-driven decision-making.

–

Key Technologies Driving Change in Ship Management

-

IoT Sensors: Monitor engine wear, emissions, and onboard equipment health.

-

AI for Voyage Optimization: Used by commercial teams to plan efficient voyages.

-

Digital Twins: Let engineers simulate ship systems for safer and faster repair decisions.

-

Crew Management Software: Automates certification tracking and seafarer rotation.

-

ESG Dashboards: Help commercial teams demonstrate sustainability to clients and regulators.

–

The Role of Flag States, Class Societies, and Port Authorities

Technical managers interact directly with:

-

Classification Societies (e.g., Lloyd’s Register, ClassNK): for surveys, certificates, and compliance

-

Flag States (e.g., Panama, Liberia, Marshall Islands): for operational licenses and safety compliance

-

Port State Control (e.g., Paris MoU): for inspections and detentions

Commercial managers, meanwhile, interact more with:

-

Charterers and brokers

-

P&I Clubs and underwriters (for claims and freight disputes)

-

Bunker suppliers and port agents

Case Studies: When One Type of Management Fails

Case 1: Technical Neglect in a Profitable Ship

In 2022, a product tanker chartered to a global oil major suffered a power failure en route to Singapore. Despite strong chartering rates, poor technical upkeep led to a Port State Control detention, costing $350,000 in off-hire days and repairs (Paris MoU annual report).

Lesson: Commercial success depends on technical reliability.

Case 2: Good Vessel, Poor Commercial Use

A modern LNG vessel under excellent technical management was underutilized during a period of soaring LNG freight rates in 2023. The owner had no commercial partner and missed out on lucrative short-term charters.

Lesson: A technically perfect ship is a wasted asset without commercial vision.

–

Frequently Asked Questions (FAQ)

Can one company handle both technical and commercial ship management?

Yes, many companies (e.g., Columbia, Synergy, V.Ships) offer integrated management services, though some owners prefer to separate the roles for better control.

Who hires the crew—technical or commercial manager?

Crew management falls under technical management. Commercial managers focus on cargo and revenue, not people onboard.

Are both types of managers required on all ships?

Not always. Some owners manage one function in-house and outsource the other. For example, a technical manager might maintain the ship, while the owner handles chartering.

Do both types need to follow IMO regulations?

Yes, though their focus differs. Technical managers focus on SOLAS, MARPOL, and ISM. Commercial managers pay attention to CII, ETS, and SEEMP performance.

Which is more important—technical or commercial management?

Both are equally vital. One ensures the ship floats and functions. The other ensures it earns money.

Conclusion: Two Sides of the Same Coin

Technical and commercial ship management are not competing forces—they’re collaborative engines driving vessel performance. One maintains the ship; the other monetizes it. Without balance, shipping operations fail—whether it’s mechanical failure or financial underperformance.

For shipowners, understanding the strengths and functions of both is crucial in choosing the right partner. For maritime professionals, knowing the difference opens career pathways tailored to your skills—engineering, navigation, logistics, or commercial strategy.

In the end, a ship must not only sail. It must sail safely—and profitably.

References

-

Clarksons Research. (2024). World Fleet Statistics. https://www.clarksons.net

-

International Maritime Organization (IMO). Conventions and Codes. https://www.imo.org

-

Lloyd’s List Intelligence. (2024). Ship Management Insights. https://lloydslist.maritimeintelligence.informa.com

-

Thetius. (2023). Digitalization in Maritime Maintenance. https://thetius.com

-

Paris MoU. (2023). Annual Report on PSC Inspections. https://www.parismou.org

-

Marine Insight. Ship Management Explained. https://www.marineinsight.com

-

Lloyd’s Maritime Academy. (2024). Voyage Optimization Trends. https://www.lloydsmaritimeacademy.com

2 thoughts on “Difference Between Technical and Commercial Ship Management: A Comprehensive Guide”