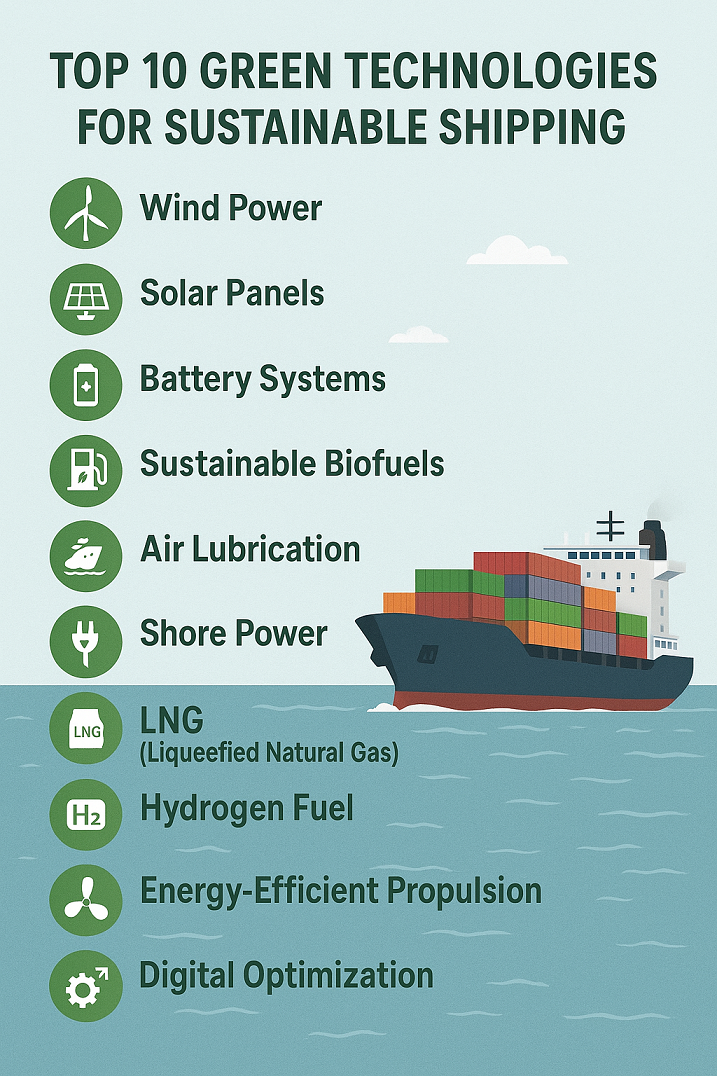

Discover the top 10 green technologies transforming sustainable shipping. Learn how innovation is reducing emissions, cutting fuel costs, and helping the maritime industry meet global climate targets.

Why Green Technologies Matter in Modern Maritime Operations

Shipping is the engine of global trade—responsible for transporting over 80% of global goods by volume. Yet, it is also a significant contributor to greenhouse gas (GHG) emissions. According to the International Maritime Organization (IMO), maritime transport accounts for approximately 2.89% of global CO₂ emissions, and that number is projected to rise if mitigation efforts stall.

As climate concerns grow, sustainability in shipping is no longer optional—it is a strategic imperative. The IMO’s revised GHG Strategy aims for net-zero emissions by 2050, backed by measures such as the Energy Efficiency Existing Ship Index (EEXI) and the Carbon Intensity Indicator (CII).

To meet these ambitious goals, shipowners, operators, and shipbuilders are turning to green technologies—innovations designed to reduce carbon footprints, optimize fuel use, and enable cleaner voyages across the world’s oceans.

This article explores the top 10 green technologies revolutionizing sustainable shipping, offering practical insights, case studies, and future outlooks for maritime professionals.

1. Wind-Assisted Propulsion Systems

Modern shipping is rediscovering wind—not with canvas sails, but with rotors, wings, and automated kites. Wind-assist systems reduce reliance on fossil fuels by using aerodynamic devices to generate thrust.

Popular Technologies:

-

Flettner Rotors (spinning cylinders that use the Magnus effect)

-

Rigid Sails (automated wing-like structures)

-

Towing Kites (deployed from the bow)

Case Study:

The MV Afros, equipped with Flettner rotors from Anemoi Marine Technologies, achieved up to 15% fuel savings on certain voyages.

Regulatory Edge: These technologies help ships meet CII performance ratings and EEDI requirements.

2. Air Lubrication Systems

Air lubrication systems create a layer of air bubbles between the hull and the seawater, reducing drag and thus lowering fuel consumption.

Benefits:

-

Up to 10% improvement in fuel efficiency

-

Reduced GHG and SOx emissions

-

Minimal maintenance compared to mechanical retrofits

Real-World Use:

Mitsubishi’s MALS (Mitsubishi Air Lubrication System) is installed on MOL-operated vessels, reporting significant efficiency gains.

3. Battery-Electric Propulsion

While large-scale transoceanic vessels may not be battery-powered soon, short-sea shipping and harbor operations are seeing widespread adoption of electric propulsion.

Advantages:

-

Zero emissions in operation

-

Silent propulsion—ideal for urban and sensitive marine areas

-

Reduced maintenance costs over time

Example:

The Yara Birkeland, launched in Norway, is the world’s first fully electric and autonomous cargo ship, operating without crew or emissions on short coastal routes.

4. LNG and Bio-LNG Propulsion

Liquefied Natural Gas (LNG) is considered a transitional marine fuel, reducing emissions of:

-

SOx by 100%

-

NOx by up to 85%

-

CO₂ by around 20%

Bio-LNG, derived from renewable biomass, offers carbon-neutral propulsion when blended with or replacing fossil LNG.

Industry Example:

CMA CGM has launched several LNG-powered mega-container ships, including the Jacques Saadé, aiming for immediate emission reductions while planning for future biofuel integration.

5. Hydrogen Fuel Cells

Hydrogen, when used in proton exchange membrane (PEM) or solid oxide fuel cells (SOFCs), produces only water as a byproduct. It is seen as a long-term zero-emissions solution for maritime energy.

Challenges:

-

Hydrogen storage (requires cryogenic temperatures)

-

Infrastructure and bunkering standards

-

Cost of green hydrogen production

Pilot Project: The HydroBingo ferry in Japan uses a dual-fuel system combining hydrogen and diesel, signaling early adoption in coastal fleets.

6. Ammonia as a Marine Fuel

Ammonia contains no carbon atoms, making it a carbon-free marine fuel when used in engines or fuel cells.

Pros:

-

High energy density

-

Easy to store compared to hydrogen

-

Already traded globally as a commodity

Industry Response: MAN Energy Solutions and Wärtsilä are actively developing ammonia-ready engines, expected to be commercially viable by 2025–2026.

7. Advanced Waste Heat Recovery Systems

Much of a ship engine’s energy is lost as heat. Waste Heat Recovery Systems (WHRS) capture this exhaust energy and convert it into electrical or mechanical power.

Benefits:

-

Fuel savings up to 10%

-

Reduced load on auxiliary generators

-

Lower CO₂ emissions and engine wear

Notable Implementation:

WHRS is commonly installed on LNG carriers and VLCCs, often reducing fuel bills by hundreds of thousands of dollars annually.

8. Exhaust Gas Cleaning Systems (Scrubbers)

Open-loop, closed-loop, or hybrid scrubbers remove sulfur from exhaust gases, enabling ships to use cheaper high-sulfur fuel oil (HSFO) while complying with IMO 2020 regulations.

Note:

While effective at SOx removal, open-loop scrubbers face bans in several ports due to wastewater discharge concerns, leading to greater interest in closed-loop and hybrid systems.

9. Digital Voyage Optimization Systems

Digital platforms use AI, weather routing, machine learning, and real-time vessel data to optimize:

-

Speed profiles

-

Engine loads

-

Sea routes

Tools Include:

-

Wärtsilä’s Fleet Operations Solution (FOS)

-

StormGeo’s s-Insight

-

ABB’s Ability Marine Advisory System

Benefit: Average 5–15% reduction in fuel consumption and better CII ratings.

10. Solar and Renewable Energy Integration

While solar energy alone can’t power an ocean-going vessel, it can support auxiliary systems like lighting, air conditioning, or navigation systems.

Example: The SolarWave catamaran operates fully on solar energy for its onboard systems. Japanese shipping company NYK has also piloted solar panels on large vessels to supplement hotel load power.

Real-World Case Study: NYK’s “Green Vessel” Concept

NYK Line launched its Super Eco Ship 2050 concept featuring:

-

Hydrogen fuel cells

-

Solar photovoltaic panels

-

Wind-assisted sails

-

AI-driven navigation

This conceptual vessel reflects the industry’s boldest sustainability visions—combining multiple green technologies for net-zero operation.

FAQ: Green Technologies in Sustainable Shipping

Q1: Which green technology is most commonly adopted today?

A: Wind-assist systems, air lubrication, and LNG propulsion are seeing wide adoption, particularly on large commercial vessels.

Q2: Are battery-powered cargo ships viable?

A: Yes, for short-range operations and ferries. However, range and battery weight limit their use in deep-sea shipping—for now.

Q3: Is hydrogen the future of maritime fuels?

A: Hydrogen holds promise, especially when produced from renewable sources, but it faces storage and infrastructure hurdles.

Q4: Do green technologies affect ship design?

A: Absolutely. Retrofits are often complex, while newbuilds are being designed from the keel up to accommodate alternative propulsion and energy systems.

Q5: What role do digital technologies play in sustainability?

A: AI and data analytics improve fuel efficiency, reduce idle time, and optimize performance—making them critical to achieving IMO emissions targets.

Conclusion

The future of sustainable shipping lies in technological integration, regulatory compliance, and bold innovation. The top 10 green technologies explored here are more than trends—they are the building blocks of tomorrow’s maritime industry.

As pressure mounts from regulators, customers, and climate imperatives, the question is not whether the industry will adapt—but how fast. For shipowners, educators, engineers, and cadets, embracing these technologies isn’t just smart—it’s essential for long-term viability.

References

-

International Maritime Organization. (2023). IMO GHG Strategy 2023. https://www.imo.org

-

DNV. (2023). Maritime Forecast to 2050. https://www.dnv.com

-

ICS. (2022). Reducing CO₂ Emissions from Ships. https://www.ics-shipping.org

-

MAN Energy Solutions. (2023). Ammonia Engine Development. https://www.man-es.com

-

Wärtsilä. (2023). Smart Marine Ecosystem Whitepaper. https://www.wartsila.com