Introduction

Tanker ships transporting crude oil and petroleum products require strict operational and environmental controls. Various systems and record-keeping protocols are in place to ensure compliance with MARPOL 73/78 and other regulatory frameworks. Among these, the Crude Oil Washing (COW) system, slop tanks, and the Oil Record Book (ORB) play essential roles in safety, efficiency, and pollution prevention.

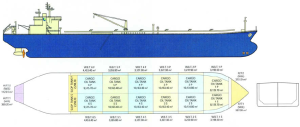

1. Crude Oil Washing (COW) System on Tankers

What is the COW system?

Crude Oil Washing (COW) is a system used on crude oil tankers to clean cargo tanks using the cargo itself (crude oil) instead of water. This system helps in:

- Removing residual oil left in the tanks after discharge.

- Reducing pollution by minimizing the amount of oil-contaminated wash water.

- Improving efficiency by recovering valuable crude oil from tank residues.

- Enhancing tank cleanliness to prevent contamination in future voyages.

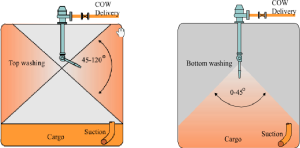

How does the COW system work?

- High-pressure crude oil jets spray the inside of the cargo tanks.

- Oil residues are loosened and drained into the cargo pump system.

- Slop tanks receive the washed oil, allowing for further separation before disposal or reuse.

Regulatory Requirements

- MARPOL Annex I, Regulation 13B mandates the use of COW on tankers above 20,000 DWT.

- The system is approved and tested before the vessel enters service.

- Crew members must maintain detailed records in the Oil Record Book (Part II).

2. Slop Tanks on Tanker Ships

What is a Slop Tank?

A slop tank is a dedicated tank on an oil tanker used to store oily residues and contaminated water produced during:

- Crude oil washing (COW)

- Ballast water operations

- Cargo tank cleaning

- Line flushing

Slop Tank Requirements on Tankers

- IMO regulations require tankers to have at least one or two slop tanks depending on size and design.

- Slop tanks allow for settling and separation of oil and water before discharge.

- Slop disposal must comply with MARPOL Annex I, ensuring no oil pollution occurs.

Common Slop Tank Operations

- Settling: Oil floats on top, water settles below.

- Decanting: Clean water is removed before disposal.

- Pumping: Residual oil is transferred back into the cargo system.

3. Oil Record Book (ORB) – Purpose and Importance

What is the Oil Record Book?

The Oil Record Book (ORB) is a mandatory logbook where ships record all oil-related operations to ensure compliance with MARPOL regulations.

Types of Oil Record Books

| ORB Part | Purpose |

|---|---|

| Part I | For machinery spaces (recording fuel oil usage, sludge disposal, bilge water treatment, etc.) |

| Part II | For cargo/ballast operations (relevant for oil tankers only, including crude oil washing, slop tank management, and discharges) |

ORB Code C – What Does It Mean?

ORB codes are specific notations used in log entries. Code C typically refers to slop tank operations, including crude oil washing, oil-water separation, and disposal procedures.

Common ORB Entries and Issues

- Missed Entries in Oil Record Book: Failing to log an oil transfer, COW operation, or slop disposal can lead to serious penalties and legal issues.

- Intertanko Guidelines for ORB Entries: Intertanko provides standardized guidelines for correct logbook entries to help ships maintain compliance and avoid fines.

Best Practices for ORB Compliance

- Ensure timely and accurate entries.

- Follow IMO and Intertanko guidelines for proper documentation.

- Keep records readily available for port state inspections.

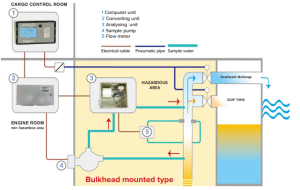

4. Oil Discharge Monitoring Equipment (ODME)

What is ODME?

The Oil Discharge Monitoring Equipment (ODME) is an automated system that:

- Monitors and controls the discharge of oily water.

- Ensures compliance with MARPOL Annex I discharge limits.

- Records all discharge data, including date, time, oil concentration, and location.

ODME Regulations

- Tankers must not discharge oil-contaminated water beyond 15 parts per million (ppm).

- ODME must be calibrated and operational before any discharge.

The Crude Oil Washing system (COW), slop tanks, and Oil Record Books (ORB) are crucial for maintaining efficiency, safety, and environmental compliance in tanker operations. Proper documentation and adherence to IMO and MARPOL regulations help prevent pollution and ensure smooth shipping operations.

I think this is one of the so much important information for me.

And i’m satisfied reading your article. However want to observation on some normal issues,

The site taste is perfect, the articles is in point of fact great : D.

Excellent task, cheers

Hello! This is my 1st comment here so I just wanted to give a quick shout out and tell you I

genuinely enjoy reading your articles. Can you suggest any other blogs/websites/forums that go over the same subjects?

Thank you!

Amazing service, perfect for our busy Manhattan lifestyle. Can’t imagine using anyone else. Really appreciate it.