Why Ship Simulators Are Central to Modern Maritime Training

Ship simulators have become one of the most critical pillars of modern maritime education and training (MET). As ships grow larger, systems more automated, and regulations more stringent, the industry increasingly relies on simulation-based training to ensure safety, competence, and regulatory compliance. Today, simulators are not merely teaching tools; they are risk-management systems that allow mariners to experience rare, dangerous, or complex scenarios without exposing vessels, cargo, crew, or the environment to harm.

The International Maritime Organization (IMO), through the STCW Convention and Code, explicitly recognises simulators as valid instruments for training, assessment, and competency demonstration. Classification societies, flag administrations, and port authorities increasingly require simulator-based evidence of competence, especially for specialised ship types and operations.

This article provides a comprehensive, SEO-optimised educational overview of the main types of ship simulators, including bridge simulators, engine room simulators, tanker operation simulators, dynamic positioning (DP) simulators, vessel traffic services (VTS) simulators, and integrated multi-domain systems. It explains what each simulator type does, who uses it, and why it matters in real-world maritime operations.

1. Bridge Simulators: Navigation, Collision Avoidance, and Command Decision-Making

Bridge simulators are the most widely recognised and extensively used ship simulators in maritime training. They replicate the ship’s navigation bridge environment, including radar, ECDIS, conning displays, propulsion controls, communications equipment, and visual surroundings.

The primary purpose of bridge simulators is to train deck officers and masters in safe navigation, situational awareness, and decision-making under realistic conditions. Modern bridge simulators recreate full 360-degree visual scenes, hydrodynamic vessel behaviour, traffic density, weather effects, and port infrastructure with high fidelity.

Training scenarios commonly include collision avoidance under COLREGs, coastal navigation, pilotage, restricted visibility operations, heavy traffic situations, emergency manoeuvring, and bridge team management. Bridge Resource Management (BRM) training is a core component, focusing on communication, leadership, workload management, and error mitigation.

From an operational perspective, bridge simulators allow trainees to experience high-risk scenarios such as near-misses, grounding threats, or navigational failures that would be unacceptable to practice on real vessels. This makes them indispensable for competency-based assessment under STCW Tables A-II/1, A-II/2, and A-II/3.

2. Full Mission Bridge Simulators vs Desktop and Part-Task Systems

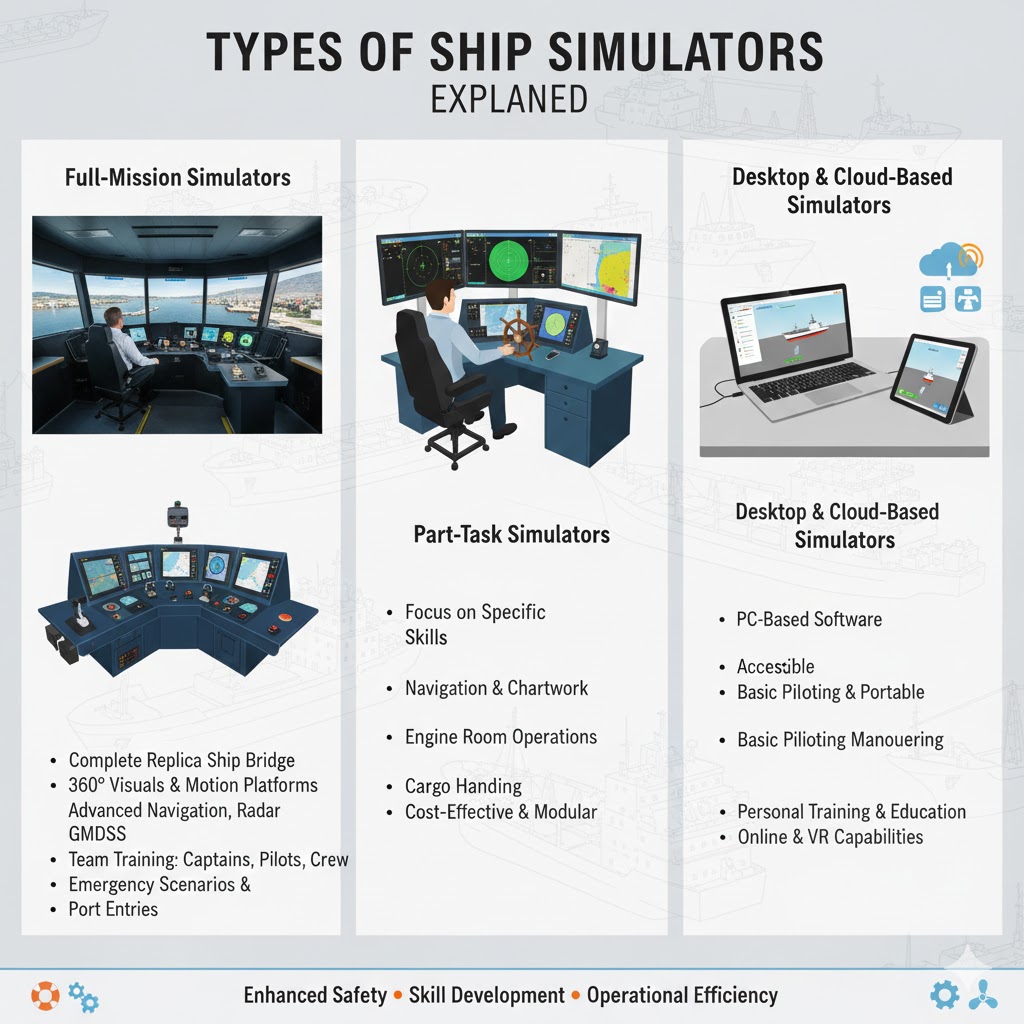

Bridge simulators exist on a spectrum of complexity and immersion. Full mission bridge simulators replicate an entire ship’s bridge with physical consoles, wraparound visuals, and multi-person operation. These systems are used primarily for advanced training, command-level assessment, and pilotage exercises.

Desktop bridge simulators, by contrast, are software-based systems typically used for foundational training, individual practice, or theory reinforcement. While less immersive, they are cost-effective and scalable, making them ideal for maritime academies and refresher training.

Part-task bridge simulators focus on specific functions such as radar plotting, ECDIS operation, or ARPA interpretation. These systems are especially useful for building procedural competence before integrating skills into full mission environments.

Together, these variants allow training providers to design progressive learning pathways, moving from basic understanding to complex, integrated operations.

3. Engine Room Simulators: Machinery Operation, Fault Diagnosis, and Emergency Response

Engine room simulators replicate the technical and operational environment of a ship’s machinery spaces. They are essential for training marine engineers, electro-technical officers (ETOs), and engine-room watchkeepers.

These simulators model main propulsion engines, auxiliary engines, boilers, pumps, electrical systems, fuel treatment units, and automation systems. The objective is to develop competence in routine operation, system monitoring, fault detection, and emergency response.

One of the most valuable aspects of engine room simulation is the ability to introduce failures deliberately. Trainees can experience scenarios such as blackout, cooling water failure, lube oil pressure loss, or automation malfunction without real-world consequences. This significantly improves troubleshooting skills and stress management.

Engine room simulators are critical for compliance with STCW Tables A-III/1, A-III/2, and A-III/6, and they play a growing role in training for energy efficiency, emissions compliance, and alternative propulsion systems.

4. Engine Room Control Room and Integrated Automation Simulation

Modern ships rely heavily on integrated automation and centralized control rooms rather than traditional manual operation. Advanced engine room simulators therefore include engine control room (ECR) simulation, replicating alarm management, power management systems, and automation logic.

These simulators train engineers to manage complex interactions between mechanical, electrical, and digital systems. They are particularly relevant for training in modern LNG carriers, cruise ships, offshore vessels, and hybrid or electric propulsion systems.

Integrated automation simulators also support training in human–machine interaction, alarm fatigue management, and safe operation under high levels of automation—an increasingly critical competence as shipping moves toward digitalisation and semi-autonomous systems.

5. Tanker Operation Simulators: Cargo Handling and Safety-Critical Procedures

Tanker operation simulators are specialised systems designed to train officers and crew involved in oil, chemical, and gas tanker operations. These simulators focus on cargo handling, ballast operations, inert gas systems, and emergency response.

Cargo control room simulators replicate pumping systems, valve logic, cargo lines, tank pressures, and monitoring systems. Trainees learn how to load, discharge, strip, and clean tanks while maintaining stability, structural integrity, and safety margins.

These simulators are essential for understanding the dynamic interaction between cargo operations and ship stability. Errors made in simulation can be analysed in detail, reinforcing best practice and regulatory compliance.

Tanker simulators are closely aligned with STCW specialised training requirements and with industry guidance from organisations such as OCIMF and SIGTTO. Given the high-risk nature of tanker operations, simulation is widely regarded as indispensable.

6. LNG, LPG, and Gas Carrier Simulators

Gas carrier simulators represent a further level of specialisation within tanker training. They model cryogenic cargo systems, reliquefaction plants, boil-off gas management, and complex safety systems.

These simulators allow trainees to understand thermodynamic processes, pressure control, and emergency shutdown procedures unique to LNG and LPG carriers. The consequences of error in gas transport are severe, making simulation-based training essential rather than optional.

As LNG shipping expands globally, demand for gas carrier simulators continues to grow, particularly for engineers and officers transitioning from conventional tanker backgrounds.

7. Dynamic Positioning (DP) Simulators: Offshore and High-Precision Operations

Dynamic Positioning simulators are used to train officers and engineers working on offshore vessels such as drilling units, construction vessels, offshore support vessels, and wind farm installation ships.

DP simulators replicate thrusters, sensors, control algorithms, and environmental forces such as wind, waves, and currents. Trainees learn to maintain vessel position and heading without anchors, often within very tight tolerances.

DP simulation is mandatory for certification under recognised schemes, including those aligned with IMCA guidance. Training focuses on normal operations, system redundancy, fault response, and emergency situations such as loss of reference systems or power failure.

The increasing complexity of offshore operations makes DP simulators one of the most technically demanding types of maritime simulation.

8. Vessel Traffic Services (VTS) Simulators: Shore-Based Traffic Management

VTS simulators are designed for training shore-based personnel responsible for monitoring and managing vessel traffic in ports, straits, and congested waterways.

These simulators replicate radar, AIS, communications systems, and traffic scenarios involving multiple vessels. Trainees practice traffic organisation, information service provision, and emergency coordination.

VTS simulation is essential for compliance with IMO Resolution A.857(20) and related guidelines. As global port congestion increases, VTS simulators play a growing role in preventing collisions, groundings, and environmental incidents.

9. Integrated Bridge–Engine–Cargo Simulators: Whole-Ship Training

One of the most advanced developments in maritime simulation is the integration of multiple simulator domains into a single training environment. Integrated simulators allow bridge teams, engine room teams, and cargo operators to train together in coordinated scenarios.

This approach reflects real shipboard operations, where decisions in one domain affect others. For example, an engine failure during cargo discharge or a navigational emergency during DP operations can be simulated with full interdepartmental interaction.

Integrated simulation supports team training, communication, and system-level thinking, which are critical for accident prevention.

10. Tug, DO, and Specialised Vessel Simulators

Specialised simulators exist for tug operations, dredgers, cable layers, and other non-conventional vessels. These simulators focus on unique hydrodynamic behaviour, towline forces, and operational constraints.

Tug simulators are particularly valuable for training in harbour assistance, escort operations, and emergency response, where forces and margins are tight and errors costly.

11. Simulator Fidelity, Validation, and Regulatory Acceptance

Not all simulators are equal. Regulatory acceptance depends on fidelity, validation, and instructor competence. IMO Model Courses and flag-state requirements specify minimum standards for visual systems, hydrodynamic modelling, and assessment capability.

Classification societies and equipment manufacturers increasingly collaborate to ensure simulators reflect real vessel behaviour accurately. Validation against sea trials and operational data is a key quality indicator.

12. The Role of Simulators in Assessment and Certification

Simulators are not only training tools but also assessment instruments. They allow objective evaluation of competence through measurable performance indicators such as reaction time, compliance with procedures, and situational awareness.

This makes simulators particularly valuable for certification, revalidation, and competency assurance in high-risk operations.

13. Digital Twins and the Future of Ship Simulation

The future of ship simulators lies in digital twin technology, where simulators are linked directly to real vessel data. This allows training scenarios to reflect actual ship configurations and operating conditions.

Digital twins support predictive maintenance, operational optimisation, and continuous learning, blurring the boundary between training and operations.

–

Conclusion: Simulators as the Backbone of Safe and Sustainable Shipping

Ship simulators are no longer optional enhancements to maritime education. They are foundational infrastructure supporting safety, efficiency, regulatory compliance, and environmental protection.

From bridge navigation to engine room emergencies, from tanker cargo operations to offshore DP control, simulators provide a controlled environment where competence is built through experience rather than trial and error.

As shipping faces new challenges—from decarbonisation to digitalisation—the role of simulators will only grow. Investing in high-quality simulation is therefore not merely an educational decision, but a strategic choice shaping the future of the maritime industry.