The management of sludge and bilge water aboard ships is a critical aspect of maritime operations, governed by stringent international regulations to prevent pollution. This article delves into the production, storage, treatment, and lawful disposal of sludge and bilge, underlining the practices onboard in alignment with the International Maritime Organization (IMO) Conventions.

Every marine vessel generates sludge and bilge water as by-products of routine operations. The treatment and disposal of these substances are regulated primarily under the International Convention for the Prevention of Pollution from Ships (MARPOL) Annex I, which sets forth the definitions, management, recording, and disposal requirements for oil residues (sludge) and bilge water.

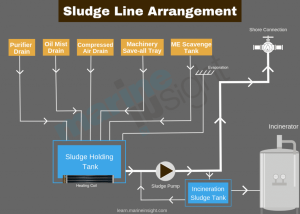

Sludge Production:Onboard sludge originates from several sources, including:

- Fuel and Lube Oil Purifiers: Regular operation generates sludge, which is expelled into designated tanks.

- Main Engine Scavenge Drains: Accumulated oil residue from cylinder lubrication is collected.

- Main Engine Stuffing Box: Leakage from this area is directed into specific tanks.

- Save-all Trays: Collects leakages from oil machinery.

- Miscellaneous Drains: Including air bottle drains and tank drains, also contribute to sludge collection.

Under MARPOL Annex I, Regulation 12, ships must have designated sludge tanks for the collection and storage of sludge.

Credit: Marineinsight

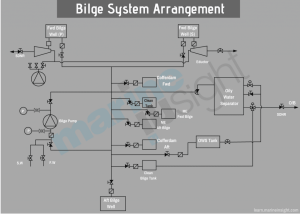

Bilge Water Generation: Bilge water is typically accumulated in the engine room’s bilge wells from various sources, including but not limited to:

- Leakage from pumps and coolers

- Condensation and maintenance activities

The discharge of bilge water is regulated under MARPOL Annex I, Regulation 15, which requires the use of an oily water separator and oil content monitor, and adherence to the 15 ppm limit.

Credit: Marineinsight

Sludge and Bilge Management

Management practices involve:

- Storage: Sludge and bilge waters are stored in dedicated tanks, with their capacities and management detailed in the ship’s International Oil Pollution Prevention (IOPP) Certificate.

- Treatment: Water content in sludge is reduced through evaporation or incineration onboard, with the use of incinerators compliant with MARPOL Annex VI, Regulation 16. Bilge water is typically treated in a bilge water separator.

- Record Keeping: All transfers and disposals must be meticulously recorded in the Oil Record Book, as per MARPOL Annex I, Regulation 17, which ensures compliance and allows for port state control inspections.

Disposal Options

- Incineration: Onboard incineration must follow the established guidelines for safe operation and emission control.

- Discharge: Bilge water discharge is permissible under specific conditions, such as the ship’s operation beyond 12 nautical miles from the nearest land and with oil content below 15 ppm.

- Shore Reception Facilities: Sludge can be offloaded to approved facilities, ensuring that it does not enter the marine environment.

The effective management of sludge and bilge on ships is imperative for environmental protection and compliance with international regulations. As technology advances, more efficient systems and processes are being developed to handle these substances, reducing the environmental footprint of maritime operations.

References

- MARPOL Annex I, “Regulations for the Prevention of Pollution by Oil”

- International Convention for the Prevention of Pollution from Ships (MARPOL)

- SOLAS (Safety of Life at Sea) Convention

- IMO Guidelines for the Implementation of MARPOL Annex I

Disclaimer: The information presented is compiled in accordance with the latest regulations and guidelines from the International Maritime Organization (IMO). However, ship operators must always refer to the current version of relevant conventions and local regulations for compliance.