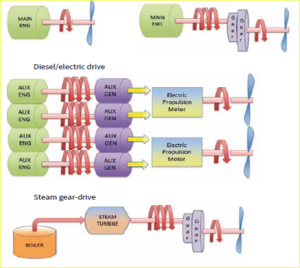

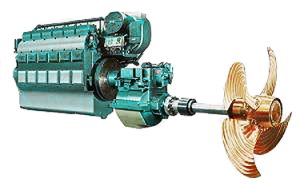

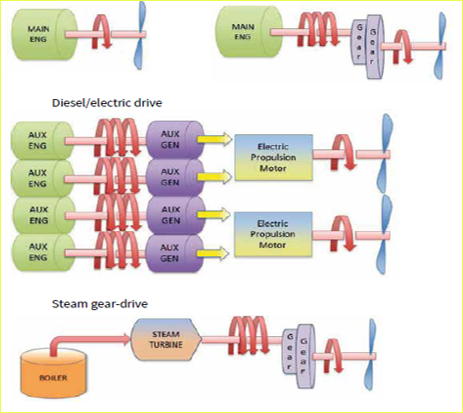

Marine propulsion is the mechanism or system used to generate thrust to move a watercraft through water. While paddles and sails are still used on some smaller boats, most modern ships are propelled by mechanical systems consisting of an electric motor or internal combustion engine driving a propeller, or less frequently, in pump-jets, an impeller. Marine engineering is the discipline concerned with the engineering design process of marine propulsion systems.

Expanding on the various ship propulsion systems, each has distinct characteristics, applications, and implications for maintenance, emissions, and fuel types:

Diesel Propulsion: Diesel engines are known for their reliability and efficiency, making them a popular choice across various ship types, including cargo ships and tankers. They can operate on a range of diesel fuels, offering a balance between performance and emissions. However, diesel engines require regular maintenance to ensure efficiency and can produce significant greenhouse gas emissions.

Steam Turbine Propulsion: Used primarily in older ships and some modern LNG carriers, steam turbines are powered by steam generated from boiling water. They were once the standard for high-speed ocean liners like the SS United States. The main challenges include the complexity of the steam generation system and the need for frequent maintenance. Steam turbines can operate on heavy fuel oil, emitting sulfur and CO2 unless treated.

Gas Turbine Propulsion: Offering high power for fast ships such as military vessels and some ferries, gas turbines work well in combination with other propulsion systems for enhanced operational flexibility. They use lighter fuels like marine diesel or natural gas, reducing sulfur emissions but still producing CO2. Gas turbines are less fuel-efficient at low speeds, presenting a challenge for diverse operational profiles.

Electric Propulsion: Seen in cruise ships and icebreakers, electric propulsion systems offer excellent maneuverability and can be powered by diesel or gas turbines, reducing fuel consumption and emissions through more efficient operation at variable speeds. The main challenges include the initial cost and complexity of the electrical systems, requiring specialized maintenance.

Sail Propulsion: Modern sail-powered ships, such as the Ecoliner Fairtransport, use wind as a renewable energy source, significantly reducing emissions and fuel consumption. The challenge lies in the dependency on wind conditions and the need for auxiliary engines for periods of calm. Maintenance is relatively low compared to engine-powered ships.

Nuclear Propulsion: Predominantly used in naval vessels, such as submarines and aircraft carriers, for their ability to operate without refueling for many years. The challenges include the high cost, complex maintenance, and disposal of nuclear waste. Emissions are virtually nonexistent in terms of greenhouse gases, making it an environmentally friendly option, though not without controversy regarding nuclear safety and waste.

| Propulsion Type | Examples | Advantages | Challenges | Emissions | Fuel Type |

|---|---|---|---|---|---|

| Diesel | Cargo ships, Tankers | Reliability, Efficiency | Greenhouse gas emissions, Maintenance | CO2, SOx | Diesel fuels |

| Steam Turbine | SS United States, LNG carriers | Effective for high-speed | Complex system, Frequent maintenance | CO2, SOx | Heavy fuel oil |

| Gas Turbine | Military vessels, High-speed ferries | High power-to-weight ratio | Less efficient at low speeds | CO2 | Marine diesel, Natural gas |

| Nuclear | Submarines, Aircraft carriers | Unlimited range | High cost, Nuclear waste | None | Nuclear |

| Electric | Cruise ships, Icebreakers | Excellent maneuverability, Efficient operation | High initial cost, Complex systems | Reduced CO2 | Diesel or gas turbines |

| Sail | Ecoliner Fairtransport | Reduced emissions, Renewable | Dependent on wind, Auxiliary engines needed | None | Wind |

The maritime industry employs a variety of propulsion systems, each with unique characteristics tailored to specific operational needs and environmental considerations. Diesel propulsion, renowned for its reliability and efficiency, is widely used in cargo ships and tankers, though it faces challenges related to greenhouse gas emissions and maintenance. Steam turbines, once the backbone of high-speed vessels like the SS United States, remain relevant in certain applications, such as LNG carriers, despite the complexity and maintenance demands. Gas turbines offer a high power-to-weight ratio suitable for military vessels and high-speed ferries, albeit less efficient at lower speeds. Nuclear propulsion, exclusive to submarines and aircraft carriers, provides an unlimited range without the need for refueling but comes with high costs and the issue of nuclear waste management. Electric propulsion, found in cruise ships and icebreakers, is praised for its manoeuvrability and efficient operation, though it requires significant initial investment and complex system management. Sail propulsion, exemplified by the Ecoliner Fairtransport, leverages wind power for reduced emissions and is a testament to the industry’s move towards renewable energy sources, despite its dependency on wind conditions and the need for auxiliary engines. Each system presents a balance of advantages and challenges, highlighting the industry’s efforts to optimize fuel efficiency, reduce environmental impact, and meet diverse operational demands.

Each propulsion type presents a unique set of advantages and challenges, from fuel efficiency and environmental impact to maintenance requirements and operational capabilities, reflecting the diverse needs of the maritime industry.

thank you for your useful information