Safe handling, stowage and securing of cargoes using ship simulators like LOADMASTER—standards, risks, and training for safer, compliant maritime operations.

A ship’s cargo is its purpose—but it is also its greatest operational risk. From container stacks and steel coils to project cargo and dangerous goods, improperly handled, stowed, or secured cargo can destabilise a vessel faster than heavy weather. In recent decades, the maritime industry has learned—often the hard way—that cargo-related incidents are not merely technical failures; they are systemic failures of planning, communication, and training.

Modern ship simulators, particularly cargo planning and stability platforms such as LOADMASTER, have emerged as critical tools to close this gap. They allow officers, cadets, and shore-based planners to “practice risk” in a safe digital environment before real-world consequences occur. Much like flight simulators transformed aviation safety, cargo simulators are reshaping how the industry understands and manages cargo risks.

Why This Topic Matters for Maritime Operations

Safe handling, stowage, and securing of cargoes directly affect vessel stability, structural integrity, crew safety, environmental protection, and regulatory compliance. Cargo-related failures remain a leading cause of groundings, capsizing, container loss, and serious injuries, particularly on container ships, ro-ro vessels, and general cargo ships.

As ship designs grow larger and cargo mixes become more complex, traditional paper-based methods and rule-of-thumb experience alone are no longer sufficient. Simulator-based training bridges the gap between regulations and real operational decision-making, ensuring that safety principles are not only known—but applied correctly under pressure.

Regulatory and Technical Foundations of Cargo Safety

International Maritime Frameworks Governing Cargo Operations

The regulatory backbone of cargo safety rests on conventions and codes developed under the International Maritime Organization. Key instruments include SOLAS chapters on stability and cargo information, the Code of Safe Practice for Cargo Stowage and Securing (CSS Code), and the International Maritime Dangerous Goods (IMDG) Code.

These instruments define what must be achieved—adequate stability margins, proper securing arrangements, and risk mitigation—but they do not prescribe how officers should internalise these principles during complex, time-pressured operations. This is where simulation becomes indispensable.

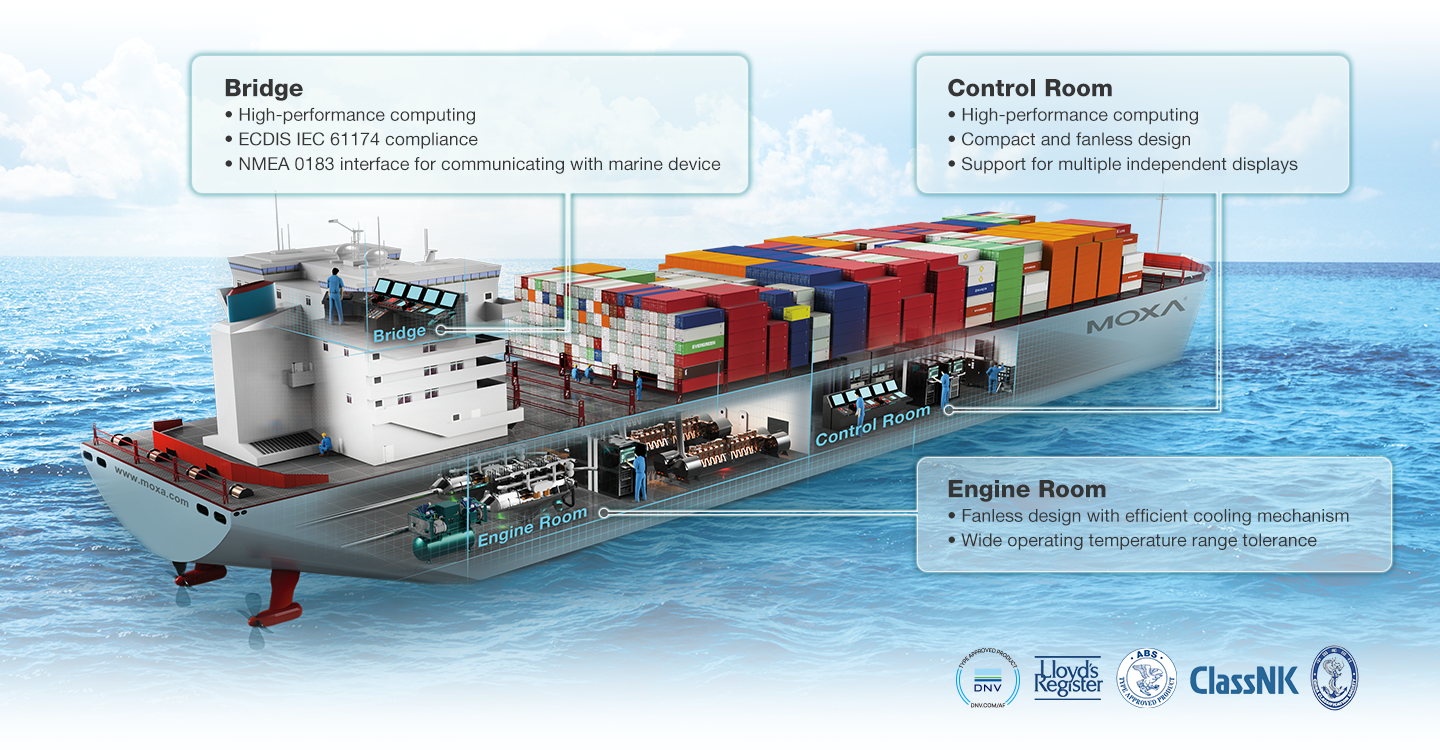

Classification Societies and Practical Interpretation

Classification societies such as DNV, Lloyd’s Register, and American Bureau of Shipping translate regulatory intent into class rules, stability booklets, and approved cargo securing manuals.

However, these documents are often dense and highly technical. Simulator platforms transform static rules into interactive decision environments, allowing users to explore “what-if” scenarios—such as partial loading, heavy lifts, or asymmetric ballast conditions—without risking ship or life.

Ship Cargo Simulators: From Calculation Tools to Learning Environments

What Is LOADMASTER and Similar Cargo Simulators?

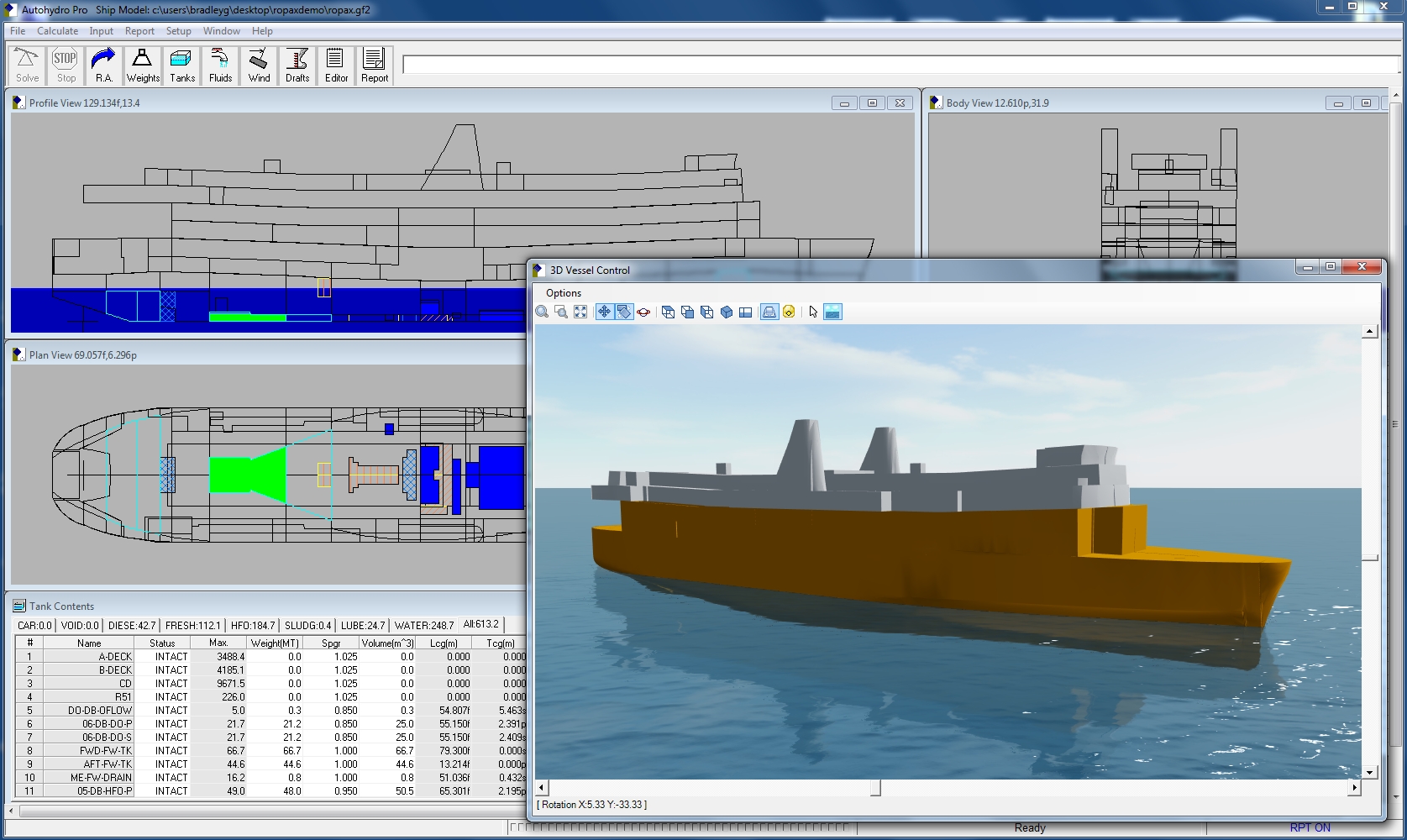

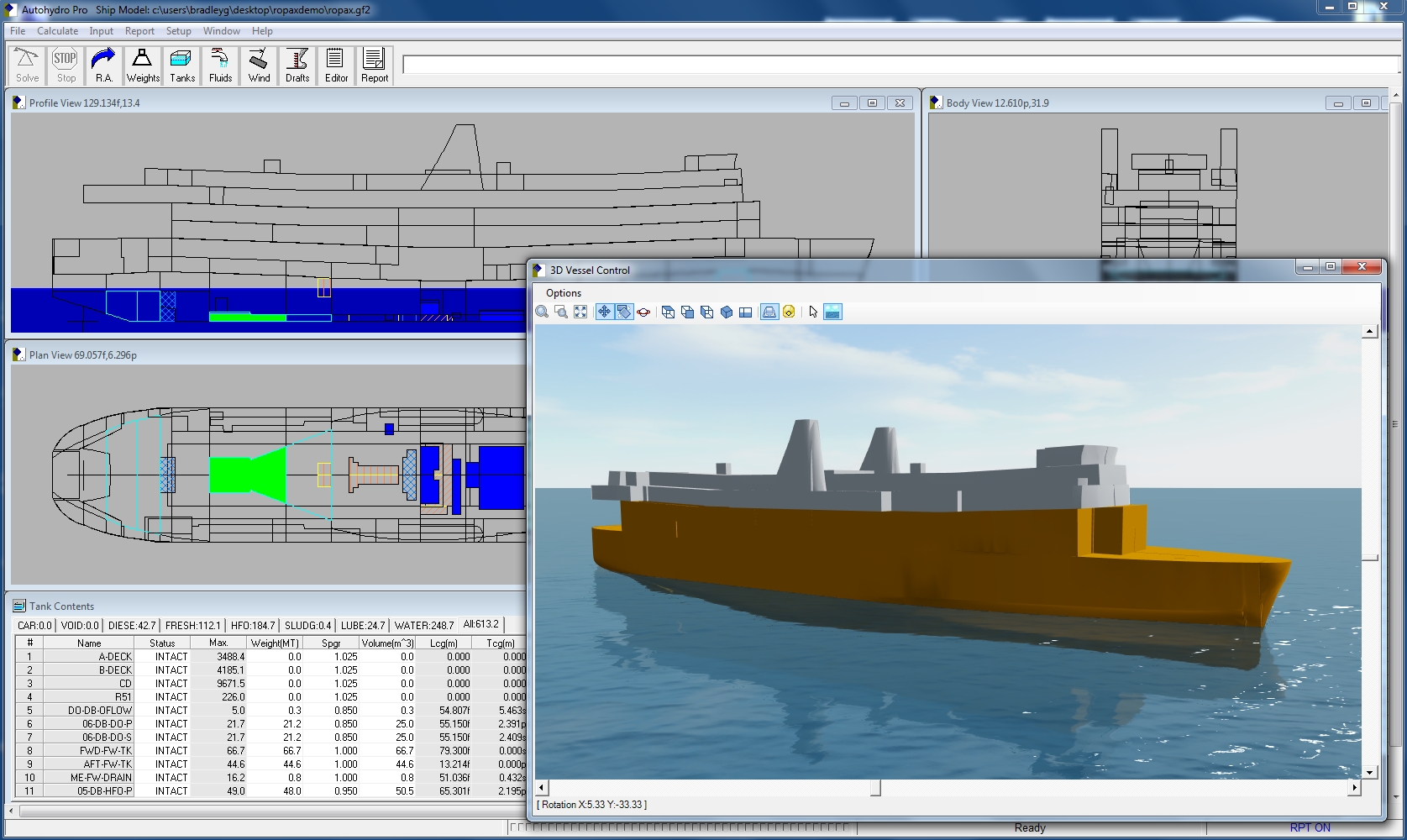

LOADMASTER is a widely used cargo planning and stability software suite employed onboard ships and in maritime academies. Originally designed as a calculation and compliance tool, it has evolved into a powerful training platform when integrated into simulator-based education.

At its core, LOADMASTER models the vessel’s hydrostatic data, structural limits, tank arrangements, and cargo spaces. Users can simulate loading sequences, ballast operations, and securing configurations, observing in real time how these decisions affect stability criteria, shear forces, bending moments, and compliance with class and flag requirements.

Why Simulation Is Superior to Static Learning

Learning cargo safety solely from textbooks is like learning to swim by reading about water. Simulation allows mistakes—incorrect GM assumptions, overloading of lashing systems, or misplacement of heavy cargo—to be experienced safely. The immediate visual feedback reinforces learning far more effectively than abstract formulas.

Safe Handling of Cargoes in a Simulator-Based Context

Understanding Cargo Characteristics Before Loading

Safe cargo handling begins long before the first sling is attached. Different cargoes behave differently: containers have predictable footprints but complex stacking loads; bulk cargoes shift; project cargo introduces high point loads; dangerous goods impose segregation and ventilation requirements.

In a simulator, trainees can explore how these characteristics influence loading plans. For example, loading a high-density cargo low in the hold improves GM but may overstress tank tops or frames. Such trade-offs become intuitive through simulation, rather than theoretical.

Human Factors and Communication

Cargo incidents often stem from miscommunication between deck officers, engine room personnel, terminal operators, and shore planners. Simulator scenarios increasingly incorporate role-based decision-making, forcing trainees to reconcile stability data with operational constraints such as crane outreach limits or ballast pump capacity.

This human-centred approach aligns with modern safety management philosophies promoted by bodies such as the International Chamber of Shipping.

Stowage Planning: Stability, Structure, and Compliance

Stability Management Through Simulation

Stability is not a static condition; it evolves throughout the voyage as fuel is consumed, ballast is adjusted, and cargo is discharged. Simulators allow officers to model these dynamic changes, ensuring that compliance exists not only at departure but at all intermediate stages.

Using LOADMASTER, trainees can visualise righting arm curves, free surface effects, and damage stability assumptions. This transforms stability from an abstract regulatory requirement into a tangible operational parameter.

Structural Load Awareness

Modern vessels are designed close to their structural limits for economic efficiency. Incorrect stowage can induce excessive shear forces or bending moments, even if stability criteria are technically met. Simulator-based training highlights this often-overlooked risk, reinforcing the principle that stability and strength must be considered together.

Securing of Cargoes: Beyond Rules to Risk Awareness

Cargo Securing as a Dynamic System

Cargo securing is frequently misunderstood as a checklist exercise—apply lashings according to the manual and proceed. In reality, securing is a dynamic system influenced by ship motion, weather, cargo geometry, and maintenance condition of securing gear.

Simulators allow trainees to experience how inadequate securing leads to progressive failure. A single loosened lashing can cascade into cargo shift, loss of GM, and ultimately capsize. Seeing this unfold in a simulator leaves a lasting impression that no classroom lecture can replicate.

Weather Routing and Operational Decisions

Advanced training scenarios integrate weather data, teaching officers how route selection and speed management affect cargo safety. Reducing speed or altering course may significantly reduce accelerations acting on cargo, a lesson increasingly emphasised by investigation bodies such as the Marine Accident Investigation Branch.

Challenges and Practical Solutions in Simulator-Based Cargo Training

Despite their advantages, simulators are not a panacea. One challenge is overreliance on “perfect data.” Real ships deal with incomplete cargo information, last-minute changes, and human error. Effective training therefore deliberately introduces uncertainty—missing weights, conflicting cargo manifests, or equipment limitations.

Another challenge is ensuring alignment between simulator models and the actual ship. Regular updates, validation against class-approved stability booklets, and instructor competence are essential. When implemented correctly, simulators do not replace experience; they accelerate and deepen it.

Case Studies and Real-World Applications

Container Loss Incidents and Lessons Learned

High-profile container losses in recent years have drawn attention to securing failures and stability misjudgements. Investigations frequently highlight improper lashing, underestimated dynamic loads, and inadequate voyage planning. Simulator-based reenactments of such incidents are now used in advanced training, allowing officers to analyse decisions step by step and understand how small deviations escalate into major accidents.

Training Academies and Flag State Expectations

Maritime administrations and training institutions increasingly recognise simulator-based cargo training as best practice. Guidance aligned with IMO Model Courses and STCW competency frameworks supports the integration of cargo simulators into officer certification pathways, particularly for masters and chief mates.

Future Outlook and Maritime Trends

Digital Twins and Predictive Cargo Safety

The next evolution of cargo simulators lies in digital twins—live models of ships updated with sensor data, weather forecasts, and operational inputs. These systems will allow predictive assessment of cargo risks days in advance, not merely compliance checks at departure.

Integration with Autonomous and Smart Shipping

As automation increases, human oversight becomes even more critical. Simulator training will shift from manual calculation to supervisory control, ensuring that officers understand not only what the system recommends, but why. This competency is essential for trust, safety, and regulatory acceptance.

Frequently Asked Questions

What is the main benefit of using cargo simulators like LOADMASTER?

They transform abstract regulations into practical, experience-based learning, reducing real-world cargo incidents.

Are simulators accepted under international training standards?

Yes. Simulator-based training aligns with IMO Model Courses and STCW competency requirements when properly implemented.

Can simulators replace onboard experience?

No. They complement experience by accelerating learning and exposing trainees to rare but high-risk scenarios.

Do simulators cover dangerous goods?

Advanced systems model IMDG segregation, ventilation, and emergency response scenarios.

Are these systems used only in academies?

No. Many ships use them onboard for voyage planning and decision support.

How often should simulator models be updated?

Whenever ship modifications occur and in line with class-approved stability data.

Conclusion

Safe handling, stowage, and securing of cargoes remain foundational to maritime safety. Ship simulators such as LOADMASTER represent a decisive shift from compliance-based learning to competence-based training. By allowing officers to see, test, and understand the consequences of their decisions, simulation builds a deeper safety culture—one grounded not in fear of regulation, but in professional mastery.

For shipping companies, training institutions, and regulators alike, investing in simulator-based cargo training is no longer optional. It is a practical, proven pathway to safer ships, protected environments, and more confident maritime professionals.

References

International Maritime Organization (IMO). Code of Safe Practice for Cargo Stowage and Securing (CSS Code).

International Maritime Organization (IMO). International Convention for the Safety of Life at Sea (SOLAS).

International Chamber of Shipping (ICS). Guidelines on Cargo Securing and Ship Safety.

DNV. Stability and Load Planning Systems – Technical Guidance.

Marine Accident Investigation Branch (MAIB). Annual Reports and Cargo Safety Investigations.

UNCTAD. Review of Maritime Transport.

Lloyd’s Register. Stability and Strength Assessment Guidance.