The maritime industry is undergoing a transformative shift toward sustainability driven by international regulations, environmental concerns, and evolving market demands. At the forefront of this transformation are dual-fuel propulsion systems, which integrate conventional diesel engines with alternative fuels such as liquefied natural gas (LNG), methanol, or hydrogen. These systems offer a pragmatic pathway to reduce greenhouse gas (GHG) emissions while maintaining operational flexibility. This article explores the mechanics, advantages, challenges, and future prospects of dual-fuel propulsion systems in sustainable shipping.

Dual-fuel propulsion systems operate by combining two fuel sources—typically a conventional marine diesel oil (MDO) or heavy fuel oil (HFO) with a cleaner alternative such as LNG. The system can switch between fuels based on availability, regulatory requirements, and operational needs, ensuring optimal performance while reducing environmental impact.

Industry Applications and Case Studies

LNG-Powered Cruise Ships: Cruise lines such as Carnival Corporation have adopted dual-fuel systems powered by LNG to meet strict environmental regulations while maintaining passenger comfort. “AIDAnova,” the world’s first LNG-powered cruise ship, has set new standards in sustainable maritime tourism.

Commercial Cargo Vessels: Shipping companies like Maersk and Hapag-Lloyd are investing in dual-fuel container ships to meet emissions reduction targets. Maersk’s methanol-powered container ships aim to achieve net-zero emissions by 2050.

LNG-Powered Tankers: Oil and gas companies have deployed LNG-powered tankers with dual-fuel engines to reduce their carbon footprint while ensuring reliable energy transport.

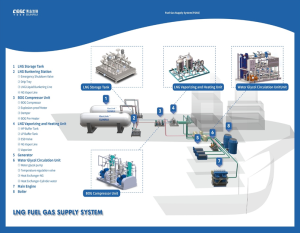

Core Components of Dual-Fuel Systems

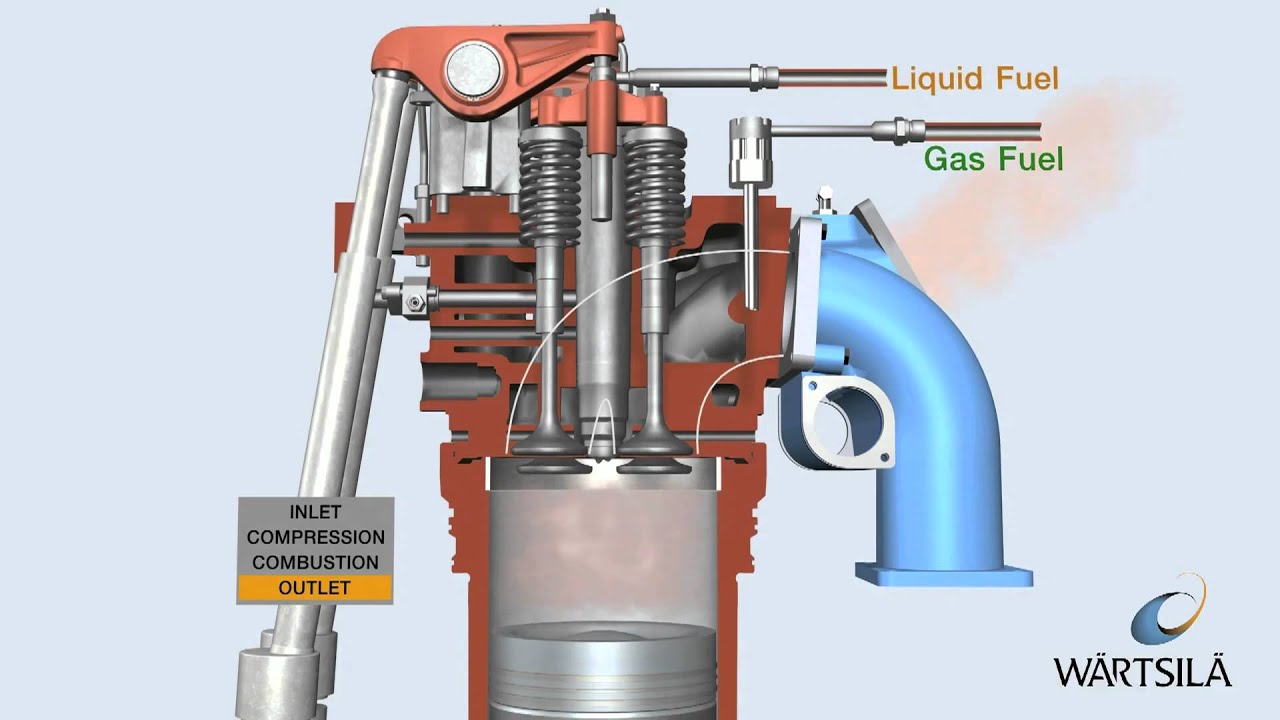

- Dual-Fuel Engines: These engines are designed to run on both diesel and alternative fuels. Advanced fuel injection systems adjust the fuel mix based on operating conditions.

- Fuel Storage Tanks: Specialized tanks store LNG, methanol, or hydrogen, equipped with advanced insulation to maintain fuel stability.

- Fuel Supply Systems: Complex piping and control systems ensure safe and efficient fuel transfer from storage to the engine.

- Control and Automation Systems: Digital monitoring platforms optimize fuel use, engine performance, and emissions control.

Benefits of Dual-Fuel Propulsion Systems

The adoption of dual-fuel propulsion systems offers significant environmental, economic, and operational advantages.

1. Environmental Sustainability

Dual-fuel systems reduce harmful emissions such as sulfur oxides (SOx), nitrogen oxides (NOx), and particulate matter. LNG-powered engines, for example, can lower CO2 emissions by up to 20% compared to conventional fuels. Case Study: The LNG-powered container ship “CMA CGM Jacques Saadé” has reduced its CO2 emissions by 25% since entering service, demonstrating the environmental potential of dual-fuel technology.

2. Regulatory Compliance

Stringent international maritime regulations, including the IMO’s MARPOL Annex VI and the upcoming Carbon Intensity Indicator (CII), are driving the adoption of cleaner propulsion systems. Dual-fuel engines ensure compliance with current and future emission standards.

3. Fuel Flexibility and Security

By enabling fuel switching, dual-fuel systems mitigate the risks of fuel shortages and price volatility. Ships can operate on the most cost-effective or regionally available fuel, reducing operational costs.

4. Operational Efficiency

Modern dual-fuel engines are designed for higher thermal efficiency, leading to lower fuel consumption and extended engine life. Advanced engine monitoring systems also optimize performance in real-time.

Dual-fuel Two-Stroke Marine Diesel Engine Dual-fuel Four-Stroke Marine Diesel Engine

Challenges and Limitations

Despite their advantages, dual-fuel propulsion systems face several technical, economic, and logistical challenges. Installing dual-fuel engines requires significant capital investment due to the complexity of engine design, fuel storage infrastructure, and retrofitting requirements.

The availability of alternative fuels like LNG, methanol, and hydrogen varies across regions. A limited global refueling infrastructure poses logistical challenges, particularly for long-haul shipping routes. Operating dual-fuel systems requires advanced crew training and specialized maintenance skills due to the complexity of fuel management and engine controls. LNG-powered engines may experience methane slip—a release of unburned methane into the atmosphere. This potent GHG must be mitigated through technological advancements such as improved combustion processes and exhaust gas treatment.

Technological Innovations Driving Adoption

Continued research and development are enhancing the performance and feasibility of dual-fuel propulsion systems in marine diesel engines. These technological advancements are critical for reducing environmental impact while maintaining operational efficiency in the maritime sector.

High-Pressure Direct Injection (HPDI): HPDI technology enables near-complete combustion of LNG, significantly reducing methane slip, a potent greenhouse gas. This system allows vessels to operate efficiently on both LNG and diesel, enhancing fuel flexibility while lowering overall emissions.

Hybrid Systems: The integration of dual-fuel engines with battery-electric systems supports eco-friendly port operations by reducing fuel consumption and emissions. Hybrid propulsion allows vessels to switch between power sources, optimizing performance based on operational requirements such as maneuvering in restricted waters or docking.

Digital Twin Platforms: Advanced digital twin technologies enable real-time monitoring of engine performance and predictive maintenance. By simulating engine operations, these platforms provide actionable insights into fuel efficiency, wear-and-tear diagnostics, and maintenance scheduling, helping shipping companies minimize operational costs while ensuring regulatory compliance.

Future Prospects and Policy Implications

As the shipping industry transitions toward a zero-emission future, dual-fuel propulsion systems are likely to play a critical bridging role. Several industry trends and policy developments will influence their adoption:

- IMO 2050 Goals: The IMO’s target to cut GHG emissions by 50% by 2050 will drive continued investment in dual-fuel technologies.

- Fuel Innovation: Emerging fuels like hydrogen, ammonia, and bio-LNG offer promising alternatives to traditional fuels.

- Global Collaboration: Industry-wide partnerships and government incentives will be essential to expand fuel infrastructure and standardize fuel safety regulations.

Dual-fuel propulsion systems represent a practical and scalable solution for reducing the environmental impact of the shipping industry while ensuring operational efficiency and fuel flexibility. While challenges related to cost, fuel availability, and methane slip persist, ongoing technological advancements and regulatory support are paving the way for wider adoption. By investing in dual-fuel technologies today, the maritime sector can navigate a sustainable future while maintaining its crucial role in global trade.

One thought on “Dual-Fuel Propulsion Systems: The Path to Sustainable Shipping”