The emergency bilge suction valve is a critical safety component in a ship’s bilge system. Its primary function is to quickly evacuate large amounts of water in the event of flooding, ensuring the ship remains buoyant and stable. Understanding its working mechanism, regulatory requirements, and differences from other bilge suction systems is essential for maritime professionals and students.

This article explores:

- The function and importance of emergency bilge suction valves.

- SOLAS regulations governing their use.

- Differences between direct bilge suction and emergency bilge suction.

- FAQs and common industry searches.

What is an Emergency Bilge Suction Valve?

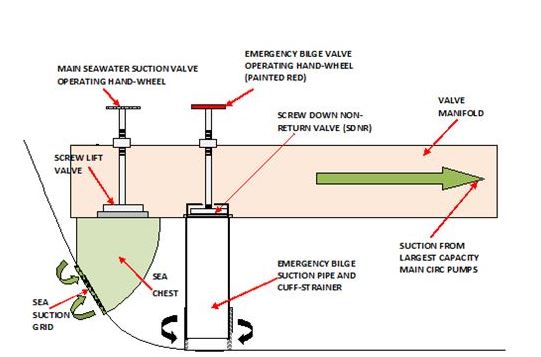

An Emergency Bilge Suction Valve (EBSV) is a manually operated valve located in the engine room. It provides an alternative high-capacity suction path to remove bilge water using the main seawater pump in emergency situations.

Key Features of an Emergency Bilge Suction Valve:

- Used during extreme engine room flooding when normal bilge pumps cannot handle the water volume.

- Directly connected to the sea water pump, enabling rapid suction.

- Manually operated, often with a quick-access lever or handwheel.

- Complies with SOLAS to enhance safety in engine rooms.

Why is the Emergency Bilge Suction Valve Important?

A ship’s bilge system handles routine water accumulation, but during emergencies, such as heavy flooding from hull breaches or machinery leaks, the normal bilge pumps may be overwhelmed.

Emergency bilge suction valves offer a crucial backup solution by:

- Preventing engine room flooding and potential loss of propulsion.

- Allowing high-volume water evacuation when normal bilge pumps fail.

- Ensuring ship safety and compliance with international regulations.

Emergency Bilge Suction vs. Direct Bilge Suction

There is often confusion between direct bilge suction and emergency bilge suction. While both serve the purpose of water removal, they have distinct differences:

| Feature | Emergency Bilge Suction | Direct Bilge Suction |

|---|---|---|

| Purpose | Used in extreme emergencies (e.g., flooding). | Used when the bilge system needs additional suction capacity. |

| Connected To | Main seawater cooling pump. | Main engine-driven bilge pump. |

| Activation | Manually operated in emergencies. | Operates automatically or manually during bilge operations. |

| Flow Rate | High capacity, designed for rapid water evacuation. | Lower than emergency bilge suction. |

| Regulation | Mandatory under SOLAS II-1/48.3. | Required but secondary to emergency systems. |

Key takeaway: Emergency bilge suction is a last-resort measure for handling flooding, whereas direct bilge suction is part of routine bilge operations.

SOLAS Regulations for Emergency Bilge Suction Valves

The International Convention for the Safety of Life at Sea (SOLAS) mandates the presence of emergency bilge suction systems in large commercial vessels.

Key SOLAS Requirements (Regulation II-1/48.3):

- The emergency bilge suction valve must be fitted inside the engine room.

- It must be directly connected to the main sea water cooling pump.

- The system should be independent from the main bilge system.

- The valve must be easily accessible and operable even in emergencies.

These regulations ensure that ships have redundant safety systems to manage extreme flooding situations.

Location and Operation of the Emergency Bilge Suction Valve

The emergency bilge suction valve is strategically placed in the engine room for quick access.

Location:

- Near the main seawater cooling pump.

- Mounted at a low point in the bilge well for maximum efficiency.

- Equipped with a manual lever or handwheel for rapid operation.

Operation:

- Identify the valve location near the seawater pump.

- Manually open the valve to activate high-capacity suction.

- The main cooling pump begins evacuating bilge water rapidly.

- Monitor water discharge to prevent system overload.

Frequently Asked Questions (FAQs)

Q1: What is the difference between direct bilge suction and emergency bilge suction?

👉 Direct bilge suction operates using the main engine-driven bilge pump, while emergency bilge suction is used during severe flooding and connected to the seawater cooling pump.

Q2: What regulation in SOLAS covers emergency bilge suction valves?

👉 SOLAS Regulation II-1/48.3 mandates that ships must have an emergency bilge suction valve connected to the main cooling water pump.

Q3: Where is the emergency bilge suction valve located in a ship?

👉 It is installed in the engine room near the main seawater cooling pump, with a manual handwheel for quick operation.

Q4: What is the function of a bilge suction valve?

👉 It allows removal of accumulated bilge water, preventing flooding and maintaining ship stability.

Q5: How do you test the emergency bilge suction valve?

👉 Regular SOLAS-compliant tests include:

- Operational checks to ensure manual opening.

- Flow rate verification using seawater pumps.

- Valve inspection for leaks or obstructions.

Conclusion

The emergency bilge suction valve is a vital safety mechanism in a ship’s engine room bilge system. Designed for high-capacity water evacuation, it ensures compliance with SOLAS regulations and prevents catastrophic flooding.

Key Takeaways:

- Essential for emergency flooding situations when normal bilge pumps fail.

- Connected to the main seawater cooling pump for high-capacity suction.

- Regulated under SOLAS II-1/48.3, ensuring maritime safety compliance.

- Regular testing and maintenance are critical for operational reliability.

For maritime professionals and students, understanding emergency bilge suction systems is crucial for ship safety and effective bilge management.

🚢 Want to learn more? For additional related information, we recommend reading the following article:

The Emergency Bilge Suction Valve in Ships: A Comprehensive Overview