World’s First Zero-Emission Harbor Tug on Port Operations

As decarbonization of shipping moves beyond the piloting phase for a range of vessel types, we start getting real results on how zero-emission technologies help reduce emissions and costs. The world`s first Zero-emission harbor tug, the ZEETUG30 was built in Turkey and put into operation in 2020. The companies that stand behind this groundbreaking design are now sharing outstanding results.

The world’s first zero-emission tug, the ZEETUG30 developed by NAVTEK Naval Technologies

Copyright : NAVTEK

The entire project started when a team at NAVTEK Naval Technologies decided to take a deep dive into existing operations of harbor tugs to see how you could cut emissions from operations by using energy storage technologies.

Corvus Energy got involved at a very early stage in the process – working closely with the design team to develop the concept design with sizing of the battery, placement, operational profile etc, and all the way until sea trial.

The concept design was given the name “ZEETUG”, short for Zero Emission Electric Tug, and the first one built has been named the “Gisas Power”. Gisas Power has since mid-2020 been operating in the Port of Tuzla, outside of Istanbul and measured results have been far beyond expectations of operational excellence.

The Zeetug in operation in Tuzla Bay, outside of Istanbul, Turkey

Copyright : NAVTEK

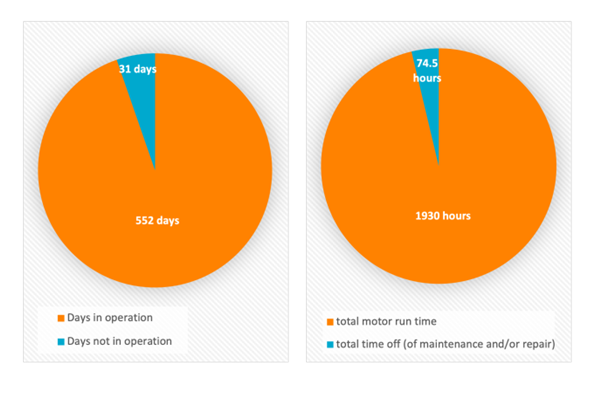

This spring NAVTEK released the operational data from the first one and a half years. Not only did NAVTEK conclude that the concept works, but it also reported that this is a highly future-proof concept for tugs going forward. The report summarizes that in the first 583 days since launch, the vessel was in operation for 552 days and completed 1532 jobs over an accumulated 1930 hours of operations. During this period the Gisas Power logged only 74 hours off-hire due to repair or maintenance.

However, the most encouraging data is the energy consumption of this tug concept:

The ZEETUG took a total charge of 380,000 kWh during this period which means the average consumption per job was only 248 kWh. Energy consumption is a constant debate when considering all-electric concepts, not only for tugs but for all vessel types.

If this had been a diesel-fueled tugboat, it would have emitted 210.1 tons of CO2 and 0.55 tons of NOX annually. Instead, the Gisas Power ZEETUG30 reduces the emission completely to zero, removing all environmental pollution. Since the start of its operations, the ZEETUG harbor tug has saved a total of 317.7 tons of CO2 and 0.83 tons of NOX.

| Emissions | Savings per year | Savings 552 days |

| CO2 Emissions | 210.1t | 317.7t |

| NOx Emissions | 0,55t | 0,83t |

“We have not only proven through the analysis, design, operational philosophy, and commitment that zero-emission for tugs is possible, but we have also proved that it will be the preferred solution for future harbor tugs,” says Ferhat Acuner, General Manager of NAVTEK Technologies.

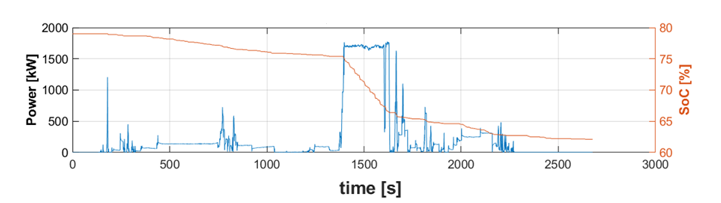

The ZEETUG is connected to the Corvus Energy vessel information portal and sends data from the battery systems every 10th second.

Henning Dahl, Chief Business Development Manager at Corvus Energy explains: “The data can give us a lot of valuable information. When analyzing the exact data from the ZEETUG we see that the actual energy consumption in real-time is a lot less than predicted during the design phase. Our life-cycle program shows us that the tug can increase its daily operations significantly in the coming years and still easily achieve the design lifetime of 10+ years on the battery system installed. The vessel has also proven that it can do continuous jobs without returning to re-charge. The average depth of discharge is in the 15-20% range of ESS installed.” The ZEETUG is fitted with 1424Kwh of Corvus Orca Energy, six battery DC/DC converters, two inverters for each of the propulsion motors, one each for the propulsion and firefighting (FI-FI) pump, and two 150 kVA off-grid converters for the tug’s hotel load. With a unique charging software and onshore quick-charging station, she can be fully charged in less than an hour.

The Zeetug has 1424 kWh of Corvus Orca Energy installed and can be fully charged in one hour.

Copyright : Corvus Energy

Why are harbor tugs ideal candidates for zero-emission operations?

The tugboat dilemma

The tugboat dilemma is an expression that has been lingering in the maritime industry for quite some time. Explained simply, it’s linked to the fact that traditional mechanical propulsion systems don’t utilize the amount of power installed on board a traditional mechanical tug. The diesel engines are sized to achieve the bollard pull rating, something rarely utilized for harbor assistance and in some cases only during the bollard pull test.

Traditional tugs operate with three diesel engines online at any time throughout a planned operation. On the other hand, an all-electric tug will operate only on batteries and consume energy only when it performs some kind of work. A diesel engine might be included to support jobs beyond normal scope, or as redundancy for unexpected events, but the batteries can serve as the main energy source. As most harbor tugs are operating within urban areas, they have a direct impact on the local air quality in addition to contributing to global emissions.

Unlike a conventional fuel-driven tug, an all-electric tug will operate only on batteries and will consume energy only when it performs some kind of work.

Copyright : NAVTEK

The work done by tugs is vital, but overall emissions are marginal compared to the larger merchant marine vessels that they safely assist in and out of our ports. Since total fuel consumption for a tug is less than most vessel types, it has been challenging to come up with business cases that can justify a fundamental change in the vessel design. This is about to change. More reliable and less expensive zero-emission solutions offered to the maritime industry, as well as the increased focus from governments and port authorities, will accelerate the energy transition towards emission-free operations.

Going forward the transition will start where pilot projects such as the ZEETUG have already proven its viability and in applications that have a direct impact on local environmental conditions.

Navtek has recently signed a new contract with Gisas for another two ZEETUG30s and a ZEETUG45 – scheduled for delivery in 2022.

Source: marinelink.com

Your article helped me a lot, is there any more related content? Thanks!

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.