When water starts rising inside a ship’s engine room, the crew has only minutes to act. Pumps roar into life, alarms sound, and engineers race to isolate leaks. In these moments, two technical terms often appear in manuals and training rooms: emergency bilge suction and bilge injection. To many cadets and even some experienced officers, these phrases sound similar and are sometimes used incorrectly as if they mean the same thing. In reality, they describe two very different principles, with different risks, different regulatory treatment, and different operational purposes.

Understanding the difference between emergency bilge suction and bilge injection is not just an academic exercise. It can determine whether a ship survives flooding or worsens it. It can also mean the difference between a correct emergency response and a serious procedural error. This article explains these two concepts in clear, practical language, compares them side by side, and links them to modern regulations, ship design, and real-world experience.

Why This Topic Matters for Maritime Operations

Flooding remains one of the most dangerous hazards in maritime operations, especially in machinery spaces where seawater pipes, cooling systems, and hull penetrations are concentrated. Reports from the Marine Accident Investigation Branch (MAIB) and the United States Coast Guard (USCG) show that many flooding incidents escalate because crews misunderstand their own pumping arrangements or use the wrong system at the wrong time. Knowing the difference between emergency bilge suction and bilge injection helps engineers choose the correct response, protects ship stability, and prevents accidental seawater entry into the vessel.

Understanding the Basics of Ship Bilge Systems

What Is a Bilge and Why Does It Matter?

The bilge is the lowest part of a ship’s internal spaces, where water naturally collects. This water may come from condensation, small leaks, cleaning operations, or machinery seepage. Under normal conditions, bilge pumps quietly remove this water and discharge it through treatment systems or overboard, in compliance with MARPOL Annex I.

In simple terms, the bilge system is like the drainage system in a building basement. It handles everyday moisture, but it is not designed to manage a burst main pipe or a sudden flood. That is why ships are required by the SOLAS Convention to have both normal and emergency means of dewatering machinery spaces (International Maritime Organization, 2023: https://www.imo.org).

Normal Bilge Pumping Arrangements

A typical ship has a bilge main running along the engine room and cargo spaces, connected to bilge wells at low points. One or more bilge pumps draw from this main. These pumps are sized for routine water accumulation and moderate leakage. Their pipes are relatively small in diameter, and their flow rates are limited.

When water ingress becomes heavy, these pumps may no longer be sufficient. This is where emergency arrangements come into play, and where the distinction between suction and injection becomes critical.

Emergency Bilge Suction Explained

Definition and Core Principle

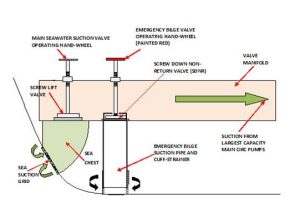

Emergency bilge suction is a special pipeline connection that allows a large-capacity pump—usually the main sea water circulating pump or fire pump—to draw water directly from the bilge. Instead of taking water from the sea, the pump takes it from the flooded engine room and discharges it overboard or to a suitable outlet.

The principle is simple: use the ship’s biggest available pump to remove water quickly. It is like using a powerful fire engine pump instead of a small domestic pump when a house is flooded.

Regulatory Foundation

SOLAS Chapter II-1 requires cargo ships of 500 gross tonnage and above to have an emergency bilge suction arrangement in machinery spaces. The regulation aims to ensure that even if the bilge main or bilge pumps fail, there is still a way to remove water using independent means (IMO, 2023: https://www.imo.org).

Classification societies interpret this requirement in technical detail. For example, DNV specifies that the emergency suction must be capable of being operated from the engine room and must have a non-return valve to prevent seawater from flowing back into the bilge (DNV Rules for Ships, 2025: https://www.dnv.com). Lloyd’s Register requires the valve to be clearly marked and protected against accidental operation (LR Rules, 2024: https://www.lr.org).

Operational Use

In practice, emergency bilge suction is used only when normal bilge pumping cannot keep up with water ingress. The engineer opens the emergency suction valve, and the main sea water pump begins drawing from the bilge instead of the sea. This can increase pumping capacity several times over.

Because this system bypasses filters and oil-water separators, it is considered an emergency-only measure. It is legally acceptable under MARPOL when the safety of the ship or life is at risk, but crews are trained to minimise environmental impact (International Chamber of Shipping, 2024: https://www.ics-shipping.org).

Bilge Injection Explained

What Is Bilge Injection?

Bilge injection describes a situation where seawater is unintentionally or intentionally introduced into the bilge system or bilge spaces through a pipe connection. Unlike emergency bilge suction, which removes water from the ship, bilge injection adds water to it.

This can occur in two main ways. The first is by design, when a sea water system is incorrectly connected to a bilge line without proper non-return protection. The second is by accident, when a valve is misaligned or a non-return valve fails, allowing seawater to flow into the bilge instead of out of it.

Why Bilge Injection Is Dangerous

Bilge injection is dangerous because it turns a drainage system into a flooding source. It is like connecting a city water main directly to your basement drain and opening the tap. Instead of removing water, you create more of it.

Many flooding incidents investigated by MAIB and AMSA have involved unintentional bilge injection. In some cases, engineers believed they were pumping water out, but in reality, they were feeding seawater into the engine room through an open valve or cross-connection (AMSA Marine Incident Reports, 2023: https://www.amsa.gov.au).

Regulatory Treatment

Unlike emergency bilge suction, bilge injection is not recognised as a safety feature. On the contrary, it is treated as a design or operational fault. SOLAS and classification rules require that bilge and sea water systems be arranged to prevent such backflow. Non-return valves, air gaps, and clear system separation are mandated to eliminate the risk of injection.

The International Association of Classification Societies (IACS) issues Unified Requirements on bilge system arrangements precisely to avoid this scenario (IACS UR P1, 2024: https://iacs.org.uk).

Emergency Bilge Suction vs Bilge Injection: Core Differences

Direction of Flow

The most fundamental difference lies in the direction of water movement. Emergency bilge suction removes water from inside the ship and discharges it outside. Bilge injection introduces water from outside into the ship’s bilge spaces.

This difference may sound obvious, but in a stressful emergency, valve misalignment can reverse this direction with serious consequences.

Purpose and Design Intent

Emergency bilge suction exists to save the ship in a flooding emergency. It is deliberately designed, tested, and regulated as a last-resort system. Bilge injection has no safety purpose. When it happens, it is either the result of poor design or human error.

Regulatory Status

Emergency bilge suction is required by SOLAS and implemented through classification rules. Bilge injection is something regulations seek to prevent. This difference alone should clarify why confusing the two is dangerous.

Risk Profile

Emergency bilge suction carries risks of pump damage and pollution, but it reduces the risk of sinking. Bilge injection increases the risk of flooding and loss of stability. In other words, one is a controlled emergency tool; the other is an uncontrolled hazard.

Key Developments and Technical Applications

Evolution of Bilge System Design

Older ships often had simpler piping systems with more cross-connections between sea water, fire, and bilge lines. While flexible, these arrangements increased the risk of bilge injection if valves were misused. Modern ships follow stricter separation principles, with dedicated lines and improved valve arrangements.

Classification societies such as ABS and Bureau Veritas now require clear colour coding and system diagrams to reduce human error (ABS Rules, 2024: https://ww2.eagle.org; BV Rules, 2024: https://www.bureauveritas.com).

Automation and Monitoring

Modern engine rooms use automation systems to monitor bilge levels and pump status. High-level alarms and trend displays help crews detect abnormal water ingress early. Some systems can alert the crew if pump discharge pressure is inconsistent with expected flow, which may indicate bilge injection or suction failure.

However, SOLAS still requires manual control of emergency bilge suction to prevent accidental operation. Technology supports decision-making, but human judgement remains central.

Environmental Safeguards

With increased focus on pollution prevention, emergency bilge suction systems are often arranged with isolation valves and clear procedures to avoid unnecessary discharge of oily mixtures. Training materials from the International Maritime Organization (IMO Model Courses) and the International Chamber of Shipping (ICS) now integrate flooding response with environmental protection principles.

Challenges and Practical Solutions

One of the biggest challenges is human error under stress. Flooding emergencies create noise, heat, and confusion. In such conditions, a wrong valve turn can transform emergency bilge suction into bilge injection. This risk is especially high on ships where valve wheels look similar or system labelling is unclear.

A practical solution is visual clarity. Many operators paint emergency suction valves in a distinct colour and install engraved nameplates. Training also plays a critical role. Engine room simulators increasingly include scenarios where students must distinguish between suction and injection paths under time pressure, reinforcing muscle memory and system understanding.

Another challenge is mechanical reliability. Emergency suction valves that are never used can seize due to corrosion. Planned maintenance systems now include periodic operation of these valves to ensure readiness. This practice is recommended by bodies such as DNV and RINA (RINA Rules for Ships, 2024: https://www.rina.org).

Case Studies and Real-World Applications

Container Ship Flooding Incident

In 2019, a container ship experienced flooding after a sea water cooling pipe ruptured. The crew attempted to use the bilge system, but misaligned valves caused seawater to enter the bilge instead of being pumped out. The investigation by MAIB found that the crew confused an emergency suction line with a sea water feed line, effectively creating bilge injection. The water level rose rapidly until the correct valve was opened and emergency suction was properly established (MAIB Report No. 5/2020: https://www.gov.uk/maib).

This case shows how theoretical knowledge must translate into practical system awareness.

Passenger Ferry Machinery Space Incident

A Baltic Sea ferry suffered a stern tube seal failure, allowing water into the machinery space. The crew immediately activated emergency bilge suction using the fire pump, stabilising the situation. The European Maritime Safety Agency (EMSA) later highlighted that the ship’s clear piping diagrams and recent crew training were decisive in avoiding confusion between suction and injection (EMSA Annual Review, 2022: https://www.emsa.europa.eu).

Here, emergency bilge suction worked exactly as intended, demonstrating its value when correctly used.

Future Outlook and Maritime Trends

As ships become more automated and energy-efficient, bilge and flooding systems are also evolving. Digital twins and real-time stability software can now model flooding progression and suggest optimal pumping strategies. In the future, these systems may warn crews not only of rising bilge levels but also of abnormal flow patterns that indicate bilge injection.

There is also growing interest in independent emergency pumps powered by batteries or alternative power sources. These could provide dewatering capability even in blackout conditions, reducing reliance on main sea water pumps. The IMO’s work on goal-based standards for ship construction suggests that future regulations may focus more on performance—how quickly water can be removed—rather than specific pipe layouts (IMO Goal-Based Standards: https://www.imo.org/en/OurWork/Safety/Pages/Goal-BasedStandards.aspx).

FAQ Section

What is the main difference between emergency bilge suction and bilge injection?

Emergency bilge suction removes water from the ship using a large pump, while bilge injection introduces water into the ship, usually by mistake.

Is bilge injection ever allowed or useful?

No. Bilge injection has no safety function and is considered a fault or error that regulations aim to prevent.

Which regulations require emergency bilge suction?

SOLAS Chapter II-1 requires emergency bilge suction arrangements for most cargo ships over 500 GT.

Why is bilge injection so dangerous?

Because it increases flooding instead of reducing it, potentially overwhelming pumps and threatening ship stability.

How can crews avoid confusing the two systems?

Clear labelling, regular training, and familiarity with the ship’s piping diagrams are essential.

Can emergency bilge suction cause pollution?

Yes, it may discharge oily water, but in an emergency threatening the ship or life, safety takes priority under MARPOL.

Conclusion and Take-Away

Emergency bilge suction and bilge injection are often mentioned together, but they stand on opposite sides of the safety spectrum. Emergency bilge suction is a carefully regulated, lifesaving system designed to remove water when all else fails. Bilge injection is an unintended and dangerous condition that regulations and good design try to eliminate.

For maritime professionals, the lesson is clear: understanding the direction of flow, the purpose of each system, and the regulatory intent behind them is not optional. It is a core competence. In emergencies, ships do not fail because of lack of equipment alone; they fail because of misunderstanding. By mastering the difference between suction and injection, engineers and officers strengthen one of the most fundamental defences against one of the sea’s oldest threats—uncontrolled flooding.

For students, trainers, and ship operators, this topic is more than theory. It is a reminder that in maritime safety, small details like valve positions and pipe connections can decide the fate of a vessel.

References

International Maritime Organization (IMO). (2023). SOLAS Consolidated Edition. https://www.imo.org

International Association of Classification Societies (IACS). (2024). Unified Requirements (UR P1). https://iacs.org.uk

Lloyd’s Register. (2024). Rules and Regulations for the Classification of Ships. https://www.lr.org

DNV. (2025). DNV Rules for Ships. https://www.dnv.com

American Bureau of Shipping (ABS). (2024). Rules for Building and Classing Steel Vessels. https://ww2.eagle.org

Bureau Veritas (BV). (2024). Rules for the Classification of Ships. https://www.bureauveritas.com

Marine Accident Investigation Branch (MAIB). (2020). Report No. 5/2020. https://www.gov.uk/maib

European Maritime Safety Agency (EMSA). (2022). Annual Review. https://www.emsa.europa.eu

International Chamber of Shipping (ICS). (2024). Shipping and the Environment. https://www.ics-shipping.org

Australian Maritime Safety Authority (AMSA). (2023). Marine Incident Reports. https://www.amsa.gov.au